Custom plastic injection molding products in China

Custom plastic injection molding products for baby carriage

The important position of the plastic injection molding products for baby carriage has no burrs, and the requirements for some sections difference are extremely high, and are controlled within 0.03mm. The glue position of the plastic products is relatively thick, and the injection molding cycle is required to be short. Due to the high and complex cooling requirements during plastic injection molding, and the plastic products are mostly deep and easy to deform. So ACO Mold injection molding company has made pre-deformation for product development companies in the early stage of plastic injection mold making.

Picture above is safety seats for baby carriage

Product parameters

Plastic product code: M150092

Injection molding material: PP

Mold Size: 387x410x93mm

Product Size: 1300x850x7855mm

Mold Weight: 6.35T

Plastic product features

1. The injection molding cycle is short.

2. The section difference is high.

3. Surface texture.

4. The mold is flipped.

5. The column is easy to stick.

Picture above is front wheel fixing part for baby carriage

Plastic product parameters

Plastic product code: M160112

Injection molding material: POM

Mold Size: 370X350X372mm

Product Size: 35x39x99mm

Mold Weight: 300Kg

Plastic product features

1. The slider position assembly size requires 0.02mm accuracy.

2. The slider position is small and cannot be cooled, so should be careful.

Above picture is hammock hook for baby carriage

Plastic product parameters

Plastic product code: M160128

Injection molding material: PP

Mold Size: 700X600X542mm

Product Size: 152x75x38mm

Mold Weight: 350T

Product features

1. The direct contact part of the hand, the product requires a high section difference.

2. The product structure is limited, the cooling is difficult, and the injection molding cycle is required to be short.

Custom plastic injection molding products for office

Picture above is cover of printer

Plastic product parameters

Plastic product Code: M160173

Injection molding material: PC

Mold Size: 450x350x323mm

Product Size: 58X57X12mm

Mold Weight: 400KG

Product features

1. The requirements for the appearance of injection molded part are high.

2. There are many small sliders, and the injection mold is easy to stick.

3. The requirements for burr are high and must be within 3 wires.

Picture above is top cover of printer

Plastic product parameters

Plastic product code: M150632

Product Material: PC+ABS (CY-6025)

Mold Size: 1030x890x777mm

Product Size: 362X430X 77.7mm

Mold Weight: 3100KG

Product features

1. Plastic parts with appearance requirements, and solve appearance problem through steam technology.

2. 1+1 gate, the number of gate is small, and the requirement for filling balance is high.

3. The PL section requirement is 0.05, which tests the injection molding accuracy and product assembly technology.

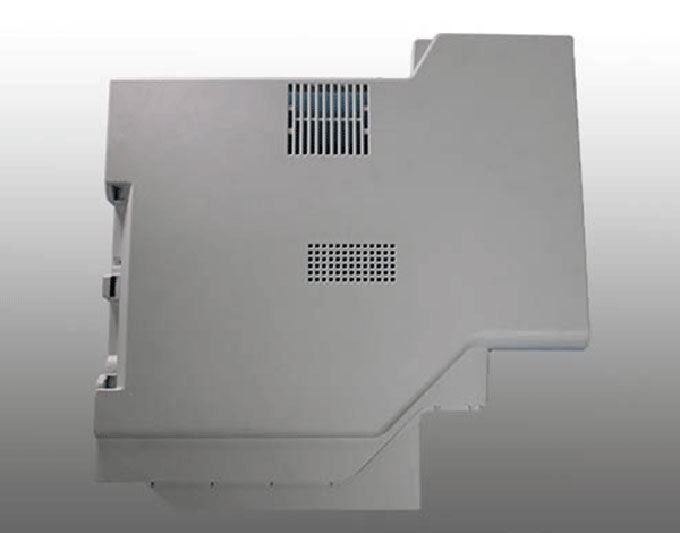

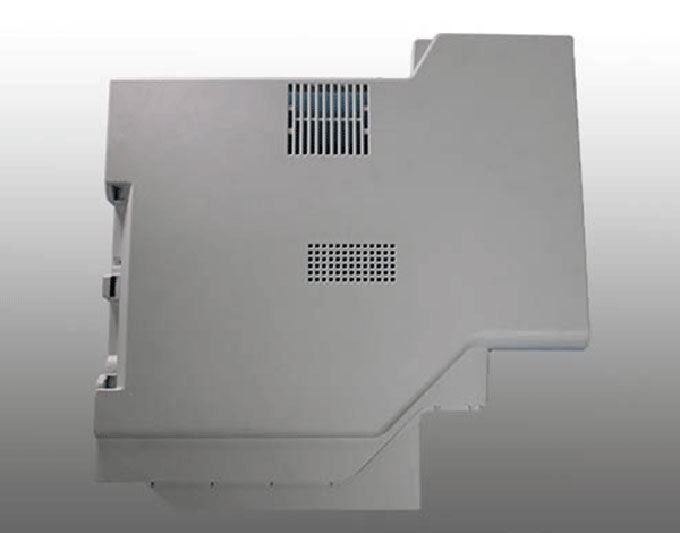

Picture above is left side panel of printer

Plastic product parameters

Plastic product code: M120375

Injection molding material: PC+ABS

Mold Size: 1100X1200X840mm

Product Size: 500X500X40mm

Mold Weight: 8650T

Product features

1. It is a close-up appearance plastic part, and the shape is complicated, and the requirement for processing machine is high.

2. No weld mark, no burr, and no shrinkage by flow-free high gloss technology

3. Use special cooling system to achieve even cooling and high polish.

Mold features

1. Hot runner mold.

2. Special mold steel, high requirements for mold texture.

3. High precision injection mold

Picture above is camera back shell

Plastic product parameters

Plastic product code: M160027

Injection molding material: PC&TPE

Mold Size: 500X350X500mm

Product Size: 62X48X20mm

Mold Weight: 800kg

Product features

1. Requirement for plastic injection molding product is high, and mold structure is complex.

2. This plastic molded product belongs to appearance plastic part, and the requirement for clamping line is high. The early delivery delay is because the burr is not processed well.

3. Because it is small sized plastic mold, so it is difficult to machine, and the requirement for dimension tolerance between mold parts is high.

4. Because the requirement for matching precision between the mold parts is high, so the mold parts need to be processed by injection mold making process with high accuracy.

Picture above is injection molding products of air conditioning

Plastic product parameters

Plastic product code: M130030C

Injection molding material: PP-MD20

Mold Size: 900mm × 600mm × 565.4mm

Product Size: 585 × 35 × 35mm

Mold Weight: 2.3T

Product features

1. There are many sliders, the requirements for assembly is high.

2. Deformation is difficult to control.

3. Size qualification rate is required to be 97% or higher.

4. Appearance material is difficult to control.

Picture above is back shell of rice cooker

Plastic product parameters

Plastic product code: M150259

Injection molding material: PP

Mold Size: 650x700x715mm

Product Size: 320x310x120mm

Mold Weight: 1300KG

Product features

1. The mold is easy to stick to the front mold, resulting in whitening. ACO Mold injection molding company adopts the addition of straight top block to make the front mold pop out (the A board bounce distance is shortened)

2. This plastic injection molding product belongs to the appearance plastic part and has high requirements for burrs and clamping lines.

Picture above is foot support plastic parts for home appliance

Plastic product parameters

Plastic product code: M180101

Injection molding material: PP

Mold Size: 550x450x392mm

Product Size: 73x70x16mm

Mold Weight: 1.5T

Product features

1. The surface is EDM processing.

2. The product tolerance is within 0.02mm

3. Scratch resistance and corrosion resistance.

We are a one-stop injection molding manufacturer located in Shenzhen China that provides R&D, mold manufacturing, injection molding, surface coating, electroplating, and product assembly etc. We have more than 9,000 square meters of standard manufacturing plant, equipped with a full set of precision mould processing workshops and ordinary mould processing workshops, measuring instrument testing laboratory, injection molding workshop, providing product companies with high-quality molding service of custom plastic injection molding products in China. The factory is equipped with a series of equipment such as CNC machining center, engraving machine, spark machine, wire cutting, grinding machine, milling machine, drilling machine and lathe etc.

If your product is still in the concept stage, welcome to ACO Mold and Contact Us. You only need to present your ideas, product features and appearance requirements. Engineers from ACO Mold injection molding factory will give you the best solution, recommend the most suitable materials, and help you take the lead in the market. We are looking forward to cooperate with your next project.

The important position of the plastic injection molding products for baby carriage has no burrs, and the requirements for some sections difference are extremely high, and are controlled within 0.03mm. The glue position of the plastic products is relatively thick, and the injection molding cycle is required to be short. Due to the high and complex cooling requirements during plastic injection molding, and the plastic products are mostly deep and easy to deform. So ACO Mold injection molding company has made pre-deformation for product development companies in the early stage of plastic injection mold making.

Picture above is safety seats for baby carriage

Product parameters

Plastic product code: M150092

Injection molding material: PP

Mold Size: 387x410x93mm

Product Size: 1300x850x7855mm

Mold Weight: 6.35T

Plastic product features

1. The injection molding cycle is short.

2. The section difference is high.

3. Surface texture.

4. The mold is flipped.

5. The column is easy to stick.

Picture above is front wheel fixing part for baby carriage

Plastic product parameters

Plastic product code: M160112

Injection molding material: POM

Mold Size: 370X350X372mm

Product Size: 35x39x99mm

Mold Weight: 300Kg

Plastic product features

1. The slider position assembly size requires 0.02mm accuracy.

2. The slider position is small and cannot be cooled, so should be careful.

Above picture is hammock hook for baby carriage

Plastic product parameters

Plastic product code: M160128

Injection molding material: PP

Mold Size: 700X600X542mm

Product Size: 152x75x38mm

Mold Weight: 350T

Product features

1. The direct contact part of the hand, the product requires a high section difference.

2. The product structure is limited, the cooling is difficult, and the injection molding cycle is required to be short.

Custom plastic injection molding products for office

Picture above is cover of printer

Plastic product parameters

Plastic product Code: M160173

Injection molding material: PC

Mold Size: 450x350x323mm

Product Size: 58X57X12mm

Mold Weight: 400KG

Product features

1. The requirements for the appearance of injection molded part are high.

2. There are many small sliders, and the injection mold is easy to stick.

3. The requirements for burr are high and must be within 3 wires.

Picture above is top cover of printer

Plastic product parameters

Plastic product code: M150632

Product Material: PC+ABS (CY-6025)

Mold Size: 1030x890x777mm

Product Size: 362X430X 77.7mm

Mold Weight: 3100KG

Product features

1. Plastic parts with appearance requirements, and solve appearance problem through steam technology.

2. 1+1 gate, the number of gate is small, and the requirement for filling balance is high.

3. The PL section requirement is 0.05, which tests the injection molding accuracy and product assembly technology.

Picture above is left side panel of printer

Plastic product parameters

Plastic product code: M120375

Injection molding material: PC+ABS

Mold Size: 1100X1200X840mm

Product Size: 500X500X40mm

Mold Weight: 8650T

Product features

1. It is a close-up appearance plastic part, and the shape is complicated, and the requirement for processing machine is high.

2. No weld mark, no burr, and no shrinkage by flow-free high gloss technology

3. Use special cooling system to achieve even cooling and high polish.

Mold features

1. Hot runner mold.

2. Special mold steel, high requirements for mold texture.

3. High precision injection mold

Picture above is camera back shell

Plastic product parameters

Plastic product code: M160027

Injection molding material: PC&TPE

Mold Size: 500X350X500mm

Product Size: 62X48X20mm

Mold Weight: 800kg

Product features

1. Requirement for plastic injection molding product is high, and mold structure is complex.

2. This plastic molded product belongs to appearance plastic part, and the requirement for clamping line is high. The early delivery delay is because the burr is not processed well.

3. Because it is small sized plastic mold, so it is difficult to machine, and the requirement for dimension tolerance between mold parts is high.

4. Because the requirement for matching precision between the mold parts is high, so the mold parts need to be processed by injection mold making process with high accuracy.

Picture above is injection molding products of air conditioning

Plastic product parameters

Plastic product code: M130030C

Injection molding material: PP-MD20

Mold Size: 900mm × 600mm × 565.4mm

Product Size: 585 × 35 × 35mm

Mold Weight: 2.3T

Product features

1. There are many sliders, the requirements for assembly is high.

2. Deformation is difficult to control.

3. Size qualification rate is required to be 97% or higher.

4. Appearance material is difficult to control.

Picture above is back shell of rice cooker

Plastic product parameters

Plastic product code: M150259

Injection molding material: PP

Mold Size: 650x700x715mm

Product Size: 320x310x120mm

Mold Weight: 1300KG

Product features

1. The mold is easy to stick to the front mold, resulting in whitening. ACO Mold injection molding company adopts the addition of straight top block to make the front mold pop out (the A board bounce distance is shortened)

2. This plastic injection molding product belongs to the appearance plastic part and has high requirements for burrs and clamping lines.

Picture above is foot support plastic parts for home appliance

Plastic product parameters

Plastic product code: M180101

Injection molding material: PP

Mold Size: 550x450x392mm

Product Size: 73x70x16mm

Mold Weight: 1.5T

Product features

1. The surface is EDM processing.

2. The product tolerance is within 0.02mm

3. Scratch resistance and corrosion resistance.

We are a one-stop injection molding manufacturer located in Shenzhen China that provides R&D, mold manufacturing, injection molding, surface coating, electroplating, and product assembly etc. We have more than 9,000 square meters of standard manufacturing plant, equipped with a full set of precision mould processing workshops and ordinary mould processing workshops, measuring instrument testing laboratory, injection molding workshop, providing product companies with high-quality molding service of custom plastic injection molding products in China. The factory is equipped with a series of equipment such as CNC machining center, engraving machine, spark machine, wire cutting, grinding machine, milling machine, drilling machine and lathe etc.

If your product is still in the concept stage, welcome to ACO Mold and Contact Us. You only need to present your ideas, product features and appearance requirements. Engineers from ACO Mold injection molding factory will give you the best solution, recommend the most suitable materials, and help you take the lead in the market. We are looking forward to cooperate with your next project.