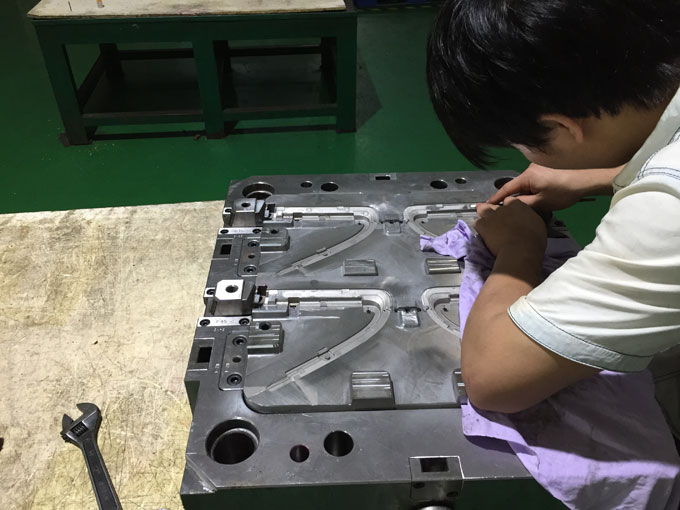

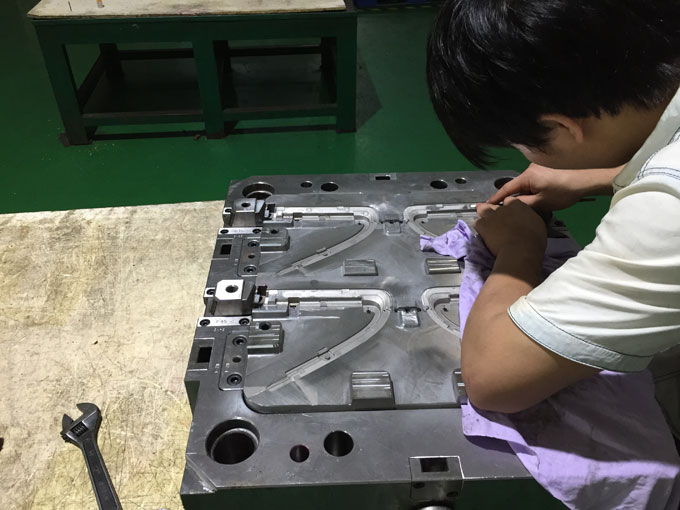

Mold Manufacturer China

The service life of the injection mold is directly related to the production cost and efficiency of injection molding parts processing. If the injection mold has a high service life, on one hand, the production cost can be reduced, and on the other hand, the processing efficiency can be improved. So how can we improve the life of injection molds? Years of practice have shown that in order to improve the service life of injection molds must be considered from the following aspects.

The heating, insulation and cooling of the mold and the clamping structure are an integral part of the design of the composite mold. The structural design directly affects the appearance and inherent quality uniformity of the product, and also affects the forming efficiency of the product.

Molding process is one of the most common and oldest molding methods for plastic materials, and it is one of the most commonly used techniques for studying material properties. It has the advantages of simple molding device, small equipment investment and simple mold structure. It is still one of the most popular production methods in today's highly developed mechanized and automated production. However, for the mold design of compression molding, few sums up the key skills in mold design. This article will explain heating, insulation and cooling design.

Molding process is one of the most common and oldest molding methods for plastic materials, and it is one of the most commonly used techniques for studying material properties. It has the advantages of simple molding device, small equipment investment and simple mold structure. It is still one of the most popular production methods in today's highly developed mechanized and automated production. However, for the mold design of compression molding, few sums up the key skills in mold design. This article will explain heating, insulation and cooling design.

Mold processing refers to the processing of forming and blanking tools, and also includes shear and die cutting dies. Under normal circumstances, the mold has two parts: the upper mold and the lower mold. The steel plate is placed between the upper and lower molds, and the material is formed under the action of a press. When the press is opened, the work-piece determined by the shape of the mold is obtained or the corresponding scrap is removed. From small electronic connectors to large parts of the car dashboard can be molded. A progressive die is a set of dies that can automatically move a machined work piece from one station to another and obtain a molded part at the last station. Mold processing technology includes: cutting die, punch blank die, composite die, extrusion die, four slide rail die, progressive die, stamping die, die-cutting die and so on.

The first step is to start with technology and establish a sound intellectual property system to achieve the full development of China's mold. After that, it will gradually apply industrial technologies that have been gradually accumulating to realize autonomous industrial production and comprehensively improve industrial competitiveness. Throughout the 12th Five-Year Plan period, China's mold will be a market environment where challenges and opportunities coexist. To achieve the full development of China's mold, the first step is to start with technology and establish a sound intellectual property system. After that, it will gradually apply industrial technologies that have been gradually accumulating to realize autonomous industrial production and comprehensively improve industrial competitiveness. Throughout the 12th Five-Year Plan period, China's mold will be a market environment where challenges and opportunities coexist.

Thermoplastic injection molding is to melt the plastic material and then inject it into the film cavity. Once the molten plastic enters the molds, it is shaped into a certain shape by the cold mold cavity. The resulting shape is often the final product, and no further processing is required before installation or use as a finished product. Many details, such as protrusions, ribs, threads can be molded in a one-step injection molding operation.

China's domestic mold technology has made rapid progress in the past two years. The main manifestations are: the popularity of mold integration manufacturing cell and technology, commercial internet extending to the mold and its industrial chain, 3D printing is widely used in mold manufacturing, intelligent mold, appearance and optimization of light weight new materials and large plastic molds, the maturity of large-scale progressive die technology, high-speed and high-reliability become important features of precision progressive die, mold standard parts tend to refine.

At present, China's annual output value of plastic molds is about 53.4 billion yuan. Do you believe that the rapid development of the Chinese economy has become more and more stringent for the plastic mold industry, thus providing a huge impetus for the development of the plastic mold industry. According to current accurate statistics, China's annual plastic mold output value reached 53.4 billion yuan, which is an existing fact.

With the rapid development of automobile manufacturing and IT manufacturing, the domestic mold factory has achieved rapid development in recent years. It is understood that the proportion of plastic molds in the mold industry in China can reach 30%. It is expected that in the future mold market, plastic mold will account for the proportion of total molds will continue to increase, and the speed of development will be faster than other molds.

With the rapid development of automobile manufacturing and IT manufacturing, the domestic mold factory has achieved rapid development in recent years. It is understood that the proportion of plastic molds in the mold industry in China can reach 30%. It is expected that in the future mold market, plastic mold will account for the proportion of total molds will continue to increase, and the speed of development will be faster than other molds.

Plastic molds are tools in the plastics processing industry that are used in conjunction with plastic molding machines to give plastic products a complete configuration and precise dimensions. According to the different molding methods, it can be divided into different types of molds.

In recent years, the plastic mold industry has developed rapidly in China, followed by increasingly fierce market competition. After joining the WTO, foreign mold manufacturers entered the domestic market and must stand out in the fierce competition. The development of mold standard parts and the professional production of molds are crucial.

As one of the pillar industries of China's light industry, the plastics industry has maintained a growth rate of over 10% in recent years. In the plastics industry, the plastics and hardware industry is very active and has become a new consumer hot spot and a new economic growth point. The market for plastics and hardware molds is promising, but it is far from the level of foreign technology.

As one of the pillar industries of China's light industry, the plastics industry has maintained a growth rate of over 10% in recent years. In the plastics industry, the plastics and hardware industry is very active and has become a new consumer hot spot and a new economic growth point. The market for plastics and hardware molds is promising, but it is far from the level of foreign technology.

This article analyzes the precautions when using injection molds. The production of injection molding products is inseparable from the molds. The quality of the molds is of crucial importance to the quality of the molded products. The mold creates value in using but gradually loses its value in using. Therefore, the operator must pay great attention to the use of the mold. Generally, the following points should be noted.

(1) Checking whether any impurities and dirt are present in the mold before using. For the remaining plastics and impurities in the mold, the copper paste must be scraped off with a cotton yarn, and then bonded with a copper knife.

(2)Reasonable choice of clamping force, which does not produce flash when molding the product and cannot be considered as high as possible, what's more it will increase power consumption and damage the transmission parts.

(3)Each transmission part should be lubricated well, so it is necessary to maintain the lubrication of these parts

(4)It is not allowed to hit any part of the mold with a heavy object such as a hammer or a hammer to avoid deformation or even damage to the mold.

(1) Checking whether any impurities and dirt are present in the mold before using. For the remaining plastics and impurities in the mold, the copper paste must be scraped off with a cotton yarn, and then bonded with a copper knife.

(2)Reasonable choice of clamping force, which does not produce flash when molding the product and cannot be considered as high as possible, what's more it will increase power consumption and damage the transmission parts.

(3)Each transmission part should be lubricated well, so it is necessary to maintain the lubrication of these parts

(4)It is not allowed to hit any part of the mold with a heavy object such as a hammer or a hammer to avoid deformation or even damage to the mold.

Injection molds becomes a very important part in the modern society. Plastic mold manufacturers almost can create anything, functional or aesthetic which broadens the vision of businessmen, artists, designers and ordinary people. In short, plastic molds almost can create anything.

With the continuous development of industrialization, China has developed into a large country in the world of injection molding processing products. China has become the world's largest exporter of injection molding products, and injection molding products have also made indelible contributions to China’s foreign trade growth. However, at the same time as rapid growth, there also have been many problems in the injection molding industry of China. So how to choose a reliable injection molding manufacturer and how is the injection mold processing factory quoting?